This post is also available in: Español (Spanish)

MAXIMUM QUALITY

Checks and audits of the components we installed

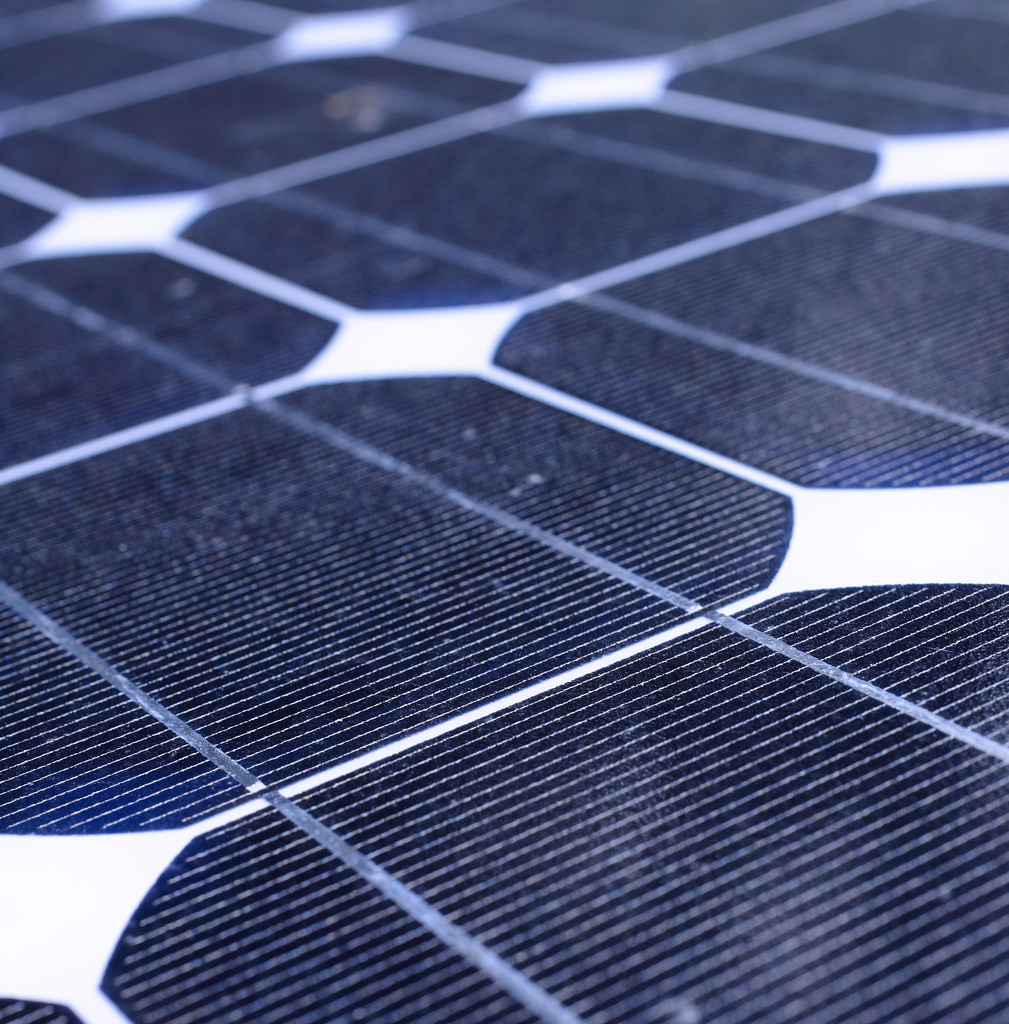

solar cells

the solar cell is the unit of power generation. Its performance along the time is the responsible of module performance.

It is the most expensive (around 60% of module cost) and fragile material of the module.

To ensure a reliable product, it is necessary to make a good characterization of the solar cells, suppliers and/or production process.

Our aim is to make a deep analysis of the cells beyond their electrical parameters.

Quality parameters of solar cells.

Dimensional characterization

Soldering test

Reflectance

Microstructure characterization

Infra-red & electro-luminiscence test

Chemical analysis

Electrical parameter measurement

módulos fv

The solar module is the unity of power generation of a pv plant.

Its performance loss along time is the main cause of non-profitable projects

good module characterization is needed to ensure a reliable product and that the installation is going to perform according to finance project.

Visual inspection (on site + lab)

Electroluminescence test (lab)

Insulation resistance, hi-pot (on site & lab) & diode tests

Infra-red testing (on-site & lab)

Electrical parameters (on site & lab)

Peel-off test and EVA cross-linking (gel content) determination

Thermal cycling, salt mist corrosion & light induced degradation tests

Spectral reflectance

pv plants

Design and plant implementation audit

Logistic, bureaucracy, security, occupational, health & safety, environment and performance analysis

Audit of key components of the plant

Not only the modules are the responsible of low energy yield.

A good dimensioning of materials like cables, layout, modules, breakers, inverter, etc is a key factor for a good performance of the pv plant.

Many problems can be easily solved with the correct know-how.